As a pipe stress engineer, you should not have to spend days or weeks determining the optimal arrangement for pipe supports.

AutoPIPE’s innovative Support Optimizer enables you to quickly evaluate multiple support arrangement alternatives using machine learning to ensure the best scenario, saving significant time and money. Benefit from the revolutionary power of artificial intelligence. With machine learning, the application does the work for you!

A pipe stress engineer only has time to do some additional test when reaches a satisfactory result. But in the background AutoPIPE Support Optimizer can test thousands of possibilities per hour and learn from the system to give you an optimized answer. And AutoPIPE gives you the eight cheapest options that complies with your specifications. Then you can modify or improve the solution based on your expertise.

AutoPIPE's Support Optimizer focuses on reducing the cost of supports and installation, while complying with the stress parameters that we have indicated, which are:

So, Why do engineers win with Support Optimizer in real life

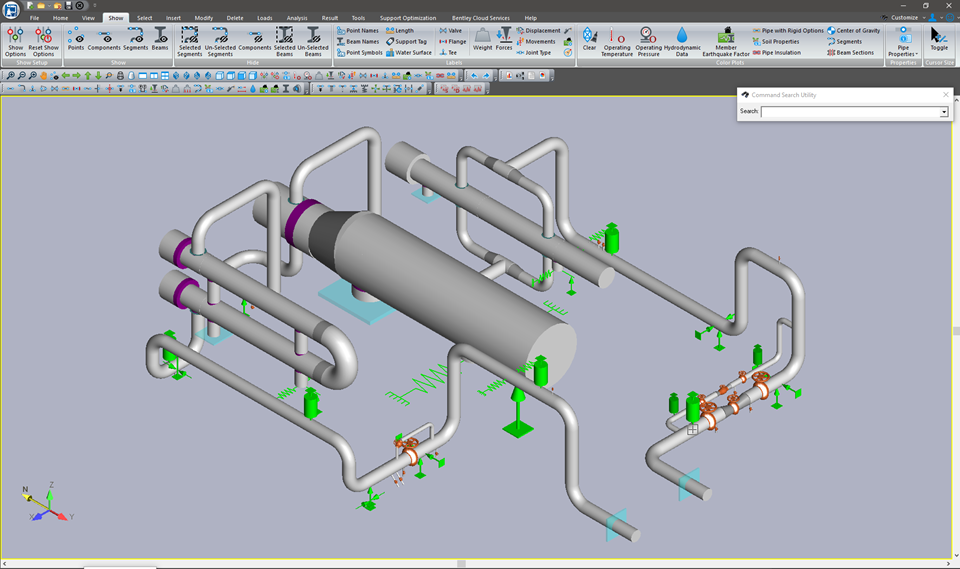

This is a real world heat exchanger system with quite restrictive nozzle loads It took this consultancy a few days to determine a satisfactory support configuration that consisted of 25 different supports.

Starting with this finished model and fixing the 6 supports on the exchangers. The optimizer in under 4 hours has found many solution options, all satisfying the design criteria and design code. The best 10 are listed here for be to select.

The arrangement for the 3647th trial, the most cost effective, looks like this. We can see at a glance that there are few supports that before and many less springs. The overall reduction in the total number of supports is 10.

The resulting support configuration is less than half of the cost of the original. Not only saving on support hardware, but also installation and operational maintenance costs.

So, who wouldn’t want to use the optimizer to win?

Original System:

Using the Support Optimizer is very simple:

Normally the program runs in the background and the stress engineer can continue with another calculation while the program searches for the optimal solutions.

The Support Optimizer will only use the minimum of support points to get the cheaper solution that complies with all the stress parameters. In the same way, it will try to avoid the most expensive supports (like constant springs) unless absolutely necessary.

The user selects the amount of resources that the Media optimizer will use to continue using the computer comfortably.