AutoPIPE can calculate in a single run several cases per Time History, such as:

The Force Vs Time profiles can be imported from any fluid transient analysis program, such as the image on the left, which corresponds to the stoppage of some pumps in a desalination plant, or they can be generated by the program itself.

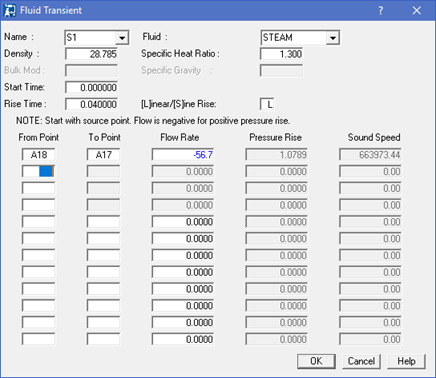

AutoPIPE integrates a Fluid Transients calculator that generates force profiles for integration by Time History. This generator is very useful for rapid valve closure phenomena, such as the tripping of a turbine, the closure of a HIPPS system, or any system where a block valve quickly closes the pipe.

The calculation of the pressure of the wave is done by Joukowski and based on the speed of the wave in the pipe AutoPIPE calculates the travel time between the elbows, the maximum imbalance of the force, the time it lasts and when it starts.

In the event of a steam hammer, the program takes the pressure and temperature conditions of the case T1 & P1.

Once the main line has been calculated, the same process must be carried out for the branches until the first closed valve. The start time should be defined as the time in which the wave passes in front of the bifurcation.

Based on these calculations, the program generates the force vs. time profiles for each straight section and a file that indicates where and when said profile should be applied.

This file also contains a scale factor in case the user needs to make calculations with a safety factor and indicate the direction vector of each of the forces.

Therefore, the user only has to indicate the integration time and if he wishes to apply the ZPA correction method.

AutoPIPE can also generate the profiles for the dischare of steam safety valves, following the guidelines and cases of ASME B31.1.

The phenomenon of packet flow, or Slug Flow, is one of the most common problems in two-phase flow systems.

When the right conditions are present, the liquid present in a gas stream forms the pattern of packets, which travel at the speed of the gas.

When reaching the elbows or curves of the system, the change in direction of the liquid package causes an unbalanced force.

For the Time History calculation of the plug flow it is necessary to perform some calculations and prepare the force profiles:

AutoPIPE automatically generates the equations for stress verification according to the code used.

In addition to generating the maximum loads and displacements of each point due to the application of the dynamic load, the AutoPIPE has a post-processor that indicates:

This data is very useful to solve problems or to see how displacements, loads and stresses are reduced. For example, the graph indicates the oscillations of the displacement curve, and therefore the frequency of oscillation. If we reduce the natural vibration mode closest to that frequency, we will reduce displacements, loads and stresses.