As each load is applied in a unique way in a sequence defined by the program or by the user, the program has all the deformations caused by the loads and can calculate the stresses that each one of them causes and combine them according to the requirements of each standard without user intervention.

As a general rule, in the Oil industry the start-up sequence is first pressurize the line and then go to the operating temperature. In AutoPIPE the sequence is:

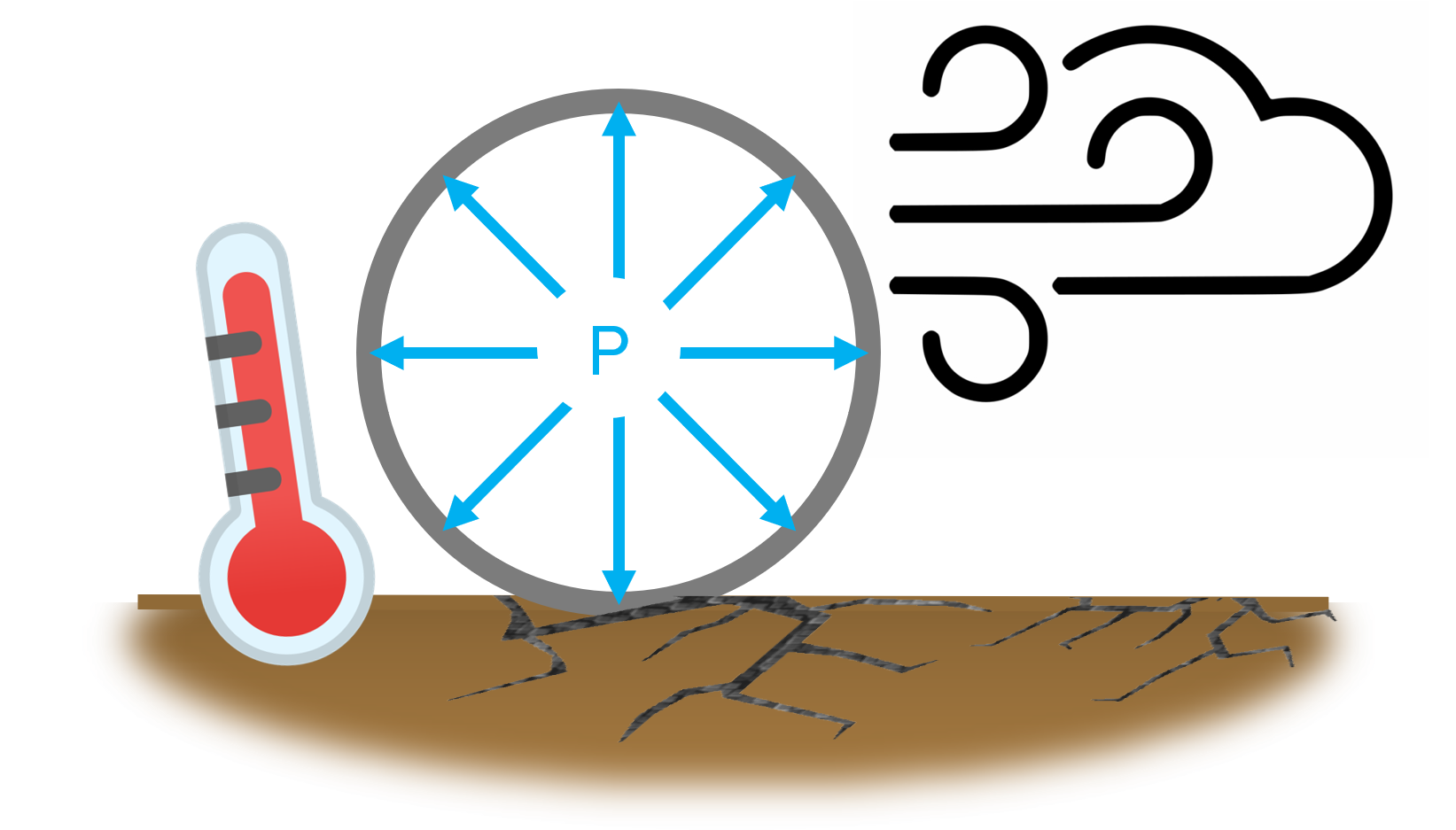

Weight Pressure Temperature

In LNG plants and other chemical plants as the Olefins units the pipe has to be cold down slowly up to a cryogenic temperature and then is pressurized. In AutoPIPE the sequence is:

Weight Temperature Pressure

This methodology is the one recommended by ASME and ensure the proper calculation of the stress. In the first sequence the gaps are closed due to the pressure extension of the pipe, but in the second sequence are closed due to the temperature. Many programs can only deal with the second one.